Polysorbates, a family of emulsifiers celebrated for their ability to create stable mixtures of oil and water, have become indispensable in various industries. In this comprehensive guide, we'll delve into the diverse applications, different types, and safety considerations surrounding polysorbates.

What are Polysorbates?

Derived from sorbitol and oleic acid, polysorbates belong to the emulsifier family. Their versatility in mixing water-soluble and oil-soluble substances makes them valuable in the formulation of a wide array of products.

Applications of Polysorbates:

1. Pharmaceuticals:

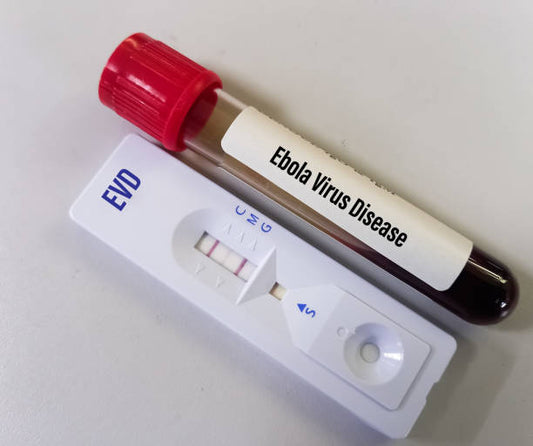

Polysorbates find extensive use in the pharmaceutical industry, acting as solubilizing agents in oral, topical, and injectable medications. They enhance the absorption of poorly water-soluble drugs.

2. Food Industry:

In the food industry, polysorbates contribute to the uniform distribution of fats in products like ice cream, margarine, and salad dressings, thereby improving texture and mouthfeel.

3. Cosmetics and Personal Care:

Common in cosmetic formulations, especially in creams, lotions, and makeup, polysorbates help blend oil and water-based ingredients for smooth and stable products.

4. Biotechnology and Research:

Polysorbates are employed in various laboratory applications, such as cell culture and molecular biology, to create stable emulsions and suspensions.

Types of Polysorbates:

-

Polysorbate 20 (Tween 20):

- Cosmetic and personal care products.

- Pharmaceutical formulations.

-

Polysorbate 40 (Tween 40):

- Found in food products like baked goods and confections.

- Used in pharmaceutical formulations.

-

Polysorbate 60 (Tween 60):

- Common in food items such as processed cheese and whipped toppings.

- Utilized in cosmetics.

-

Polysorbate 80 (Tween 80):

- Widely used in the pharmaceutical industry for drug formulations.

- Found in the food industry, especially in ice cream.

Safety Considerations:

While generally regarded as safe, it's important to consider:

-

Allergies: Individuals with known allergies to sorbitol or oleic acid should exercise caution, as polysorbates are derived from these compounds.

-

Residual Ethylene Oxide: Polysorbates are produced using ethylene oxide, and it's crucial to ensure that products are free from harmful residual amounts of this substance.

Conclusion:

Polysorbates, with their exceptional emulsifying properties, play a pivotal role in various industries. Understanding their diverse applications, different types, and safety considerations is essential for responsible and effective utilization. As with any ingredient, adherence to recommended guidelines ensures the benefits of polysorbates while prioritizing safety.

Author: Nikita Vishnoi BCA